Add-On module ZONAL CAL BLOCK

price on request

Add-On module ZONAL CAL BLOCK for BeamTool 9

The ZonalCalBlock is an Add-on module that extends the capabilities of the already powerful BeamTool ray tracing and technique simulation application.

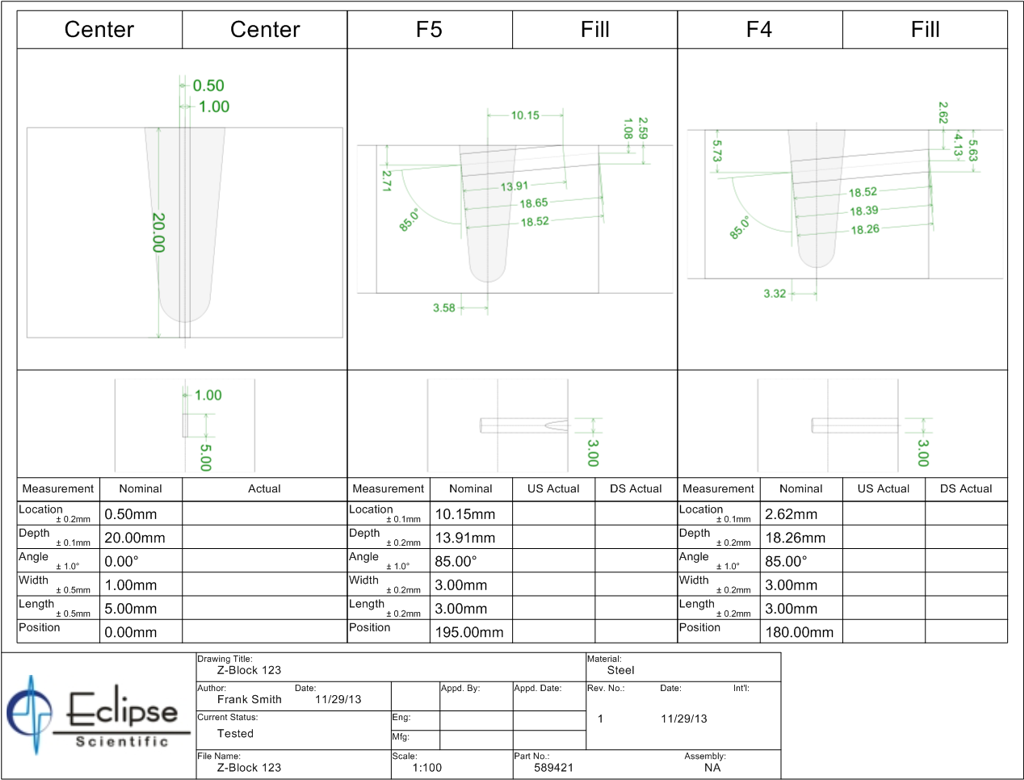

- Auto generation of a comprehensive set of drawings documenting all aspects of a calibration block to support machining and support the use of other software packages like CIVA

- Provide a set of new geometries to allow users to draw common calibration block targets, including notches, side drilled holes and flat bottom holes.

- Provide automated generation of a Z calibration block with calblock targets automatically generated for each Zonal target

This module will provide users with an expanded toolset for generating calibration block design drawings and documents.

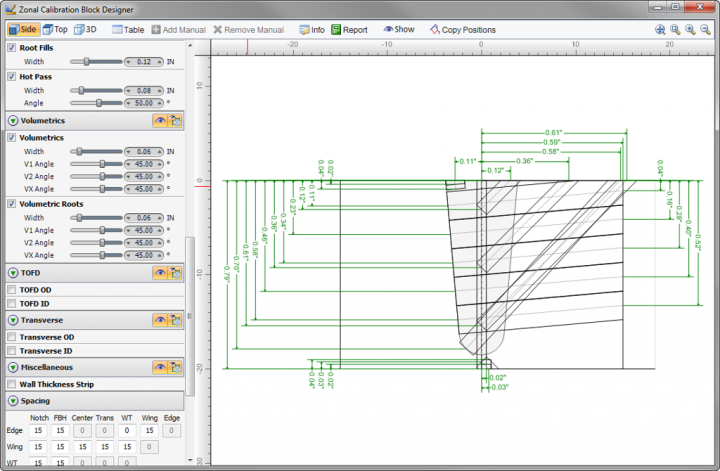

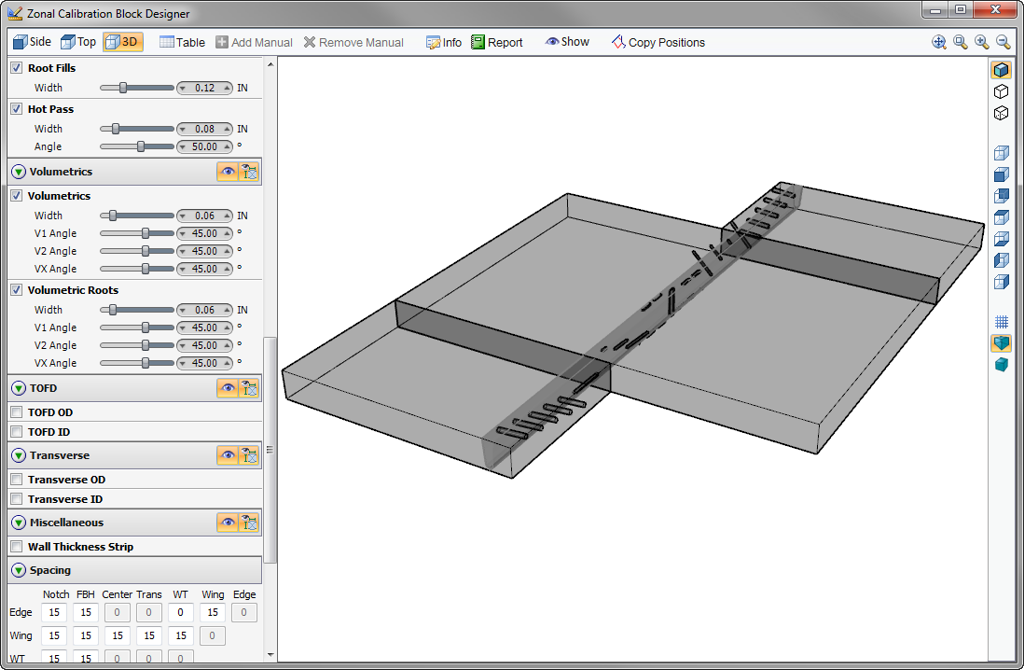

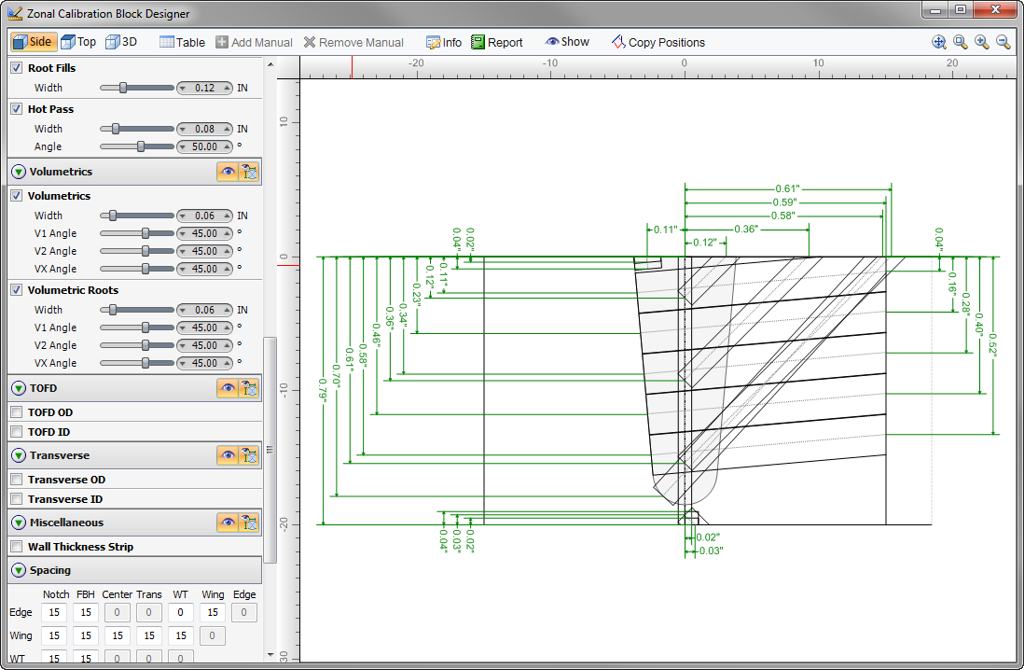

Produce a set of drawings automatically from your zonal configuration. The ZonalCalBlock add-on is a tool that is intended to automatically generate precise calibration block drawings. The generated drawings can be delivered to a machine shop for production.

The ZonalCalBlock utilizes the ESBeamTool Advanced Weld Editor, which provides the ability for users to define “regions” and “zones” within a weld bevel.

Weld regions and zones are constructed via customized algorithms, and are designed to provide optimized “full coverage” of a weld bevels’ fusion face and volume. The Advanced Weld Editor is a powerful tool which is discussed and documented elsewhere in other papers.

Taking advantage of optimized weld bevel zones, the ZonalCalBlock provides the ability for users to customize a calibration block that will include the necessary targets and notches to validate scanning procedures and techniques.

Specific target types can be turned on or off and customized as necessary to fulfill requirements

- Cap notches

- Root notches

- Fusion face flat-bottom holes

- Volumetric flat-bottom holes

- TOFD notches

- Through holes

- Transverse notches

The results of defining the targets are:

- Live renderings of side and top views of the block

- Printable reports describing each target in detail

- Exportable CAD files for further customization in external applications

Requirements

- BeamTool version 5.2 and up that is also running the ZONAL add-on

- Operating system Windows VISTA SP2 (x86, x64), Windows 7 SP1 (x86, x64), Windows 8/8.1 (x86, x64), Windows 10 (x86, x64)

- Operating system Windows Windows Server 2008 SP2 (x86, x64), Windows Server 2008 R2 SP2 (x86, x64), Windows Server 2012 (x64), Windows Server 2012 R2x64)

- Microsoft .NET Framework 4.6 or higher

- Processor 1GHz or faster

- RAM 512 MB or more

- Hard disc 4.5 GB or more

Standard package

- Add-On module Simulation as download (no shipment on data media)

- SoftLock users will receive an additional serial number with which to activate the add-on

- HardLock and FlashLock users will receive an upgrade for their HASP-USB-Key

- No additional modules (Add-on). These must be ordered separately

- OnLine Help in Englisch (no printed operating manual)

Tips for the operation and use

- The SoftLock license uses a serial number to activate BeamTool on a single computer. If you want to use the license on another computer, you must first deactivate the software on the current computer before you can reactivate it on another.

- The HardLock and FlashLock license uses a HASP USB key to activate BeamTool. BeamTool may be installed on multiple machines but will only run with the HASP key present.

Possible influences on the results

- With the calculation of ray tracing BeamTool9 uses the geometrical data of the part, and its physical data (sound velocities) entered by the user, as well as all relevant data of the selected probe and delay line at room temperature (20°C). Further influences, e.g. the surface condition of the part and temperature deviations of the probe and delay may have an unexpected effect on the sound propagation. These influences, but also the material structure (sound attenuation, scattering and un-isotropy) of the real part are not considered in BeamTool9!

BeamTool9 only calculates the results based on the sound velocity entered by the user. Possible mode conversion, that may occur with sound reflection at boundaries are not taken into consideration, and may lead to unexpected artifacts with later practical application.

The geometrical and technical data of the probes and delay lines or wedges filed in the integrated database relate to the data supplied to Eclipse Scientific by the individual probe manufacturers. Continuous development of new probes and wedges or changes by the manufacturer, even minor differences to the existing stored data, but also incorrect entries of values in the database, may have a negative influence on the calculation of sound propagation. However, with Ultrasonic inspection according to standards, probe and wedge data must always be checked using a designated reference block with artificial reflectors.

BeamTool9 always calculates the acoustical axis of the corresponding beam based on the entered probe and wedge data. Any side or grating lobes of the sound beam are not considered.

- Summary: BeamTool9 calculates the sound propagation of the Ultrasonic wave based on a simple physical model, which best describes the physics of sound propagation and reflection. Influences, as described above, may effect the simulation results of BeamTool9. Therefore it is very important to verify the results, when converting the BeamTool scan plan into practice!

Limitation of Eclipse Scientific’s Obligation & Liability

- The manufactur company Eclipse Scientific shall not be liable to Reseller or any of its customers for any special indirect, incidental or exemplary damages, including, but not limited to, loss of business, loss of profit, loss or damage resulting from the loss of data, inability to access Internet, or inability to transmit or receive information, caused by, or resulting from, delays, non-deliveries, or service interruptions caused by Eclipse Scientific or the Product, even if Eclipse Scientific has been advised of the possibility of such damages.

- Eclipse Scientific’s liability to Reseller and any customer of Reseller is limited to the purchase price received by Eclipse Scientific for the relevant Product.

*Our offer is solely meant for trade and industry, as well as for company owners. All prices are to be understood as strict net prices plus statutory VAT.